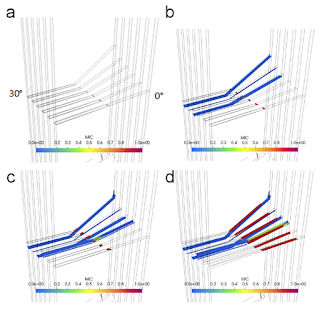

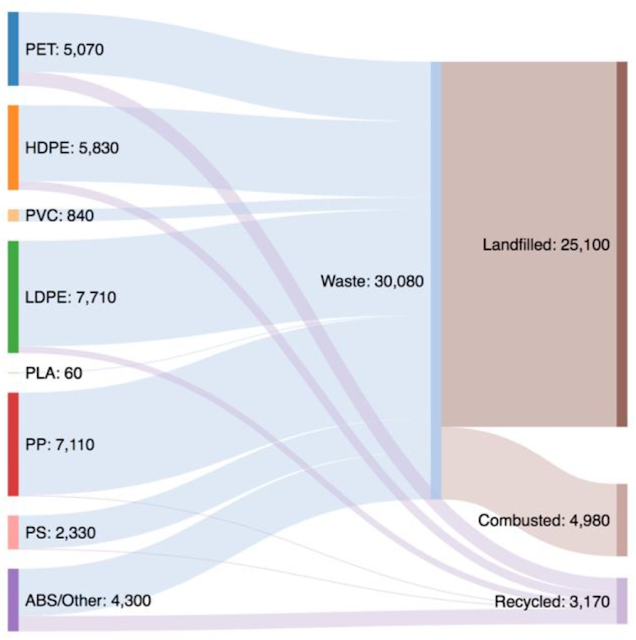

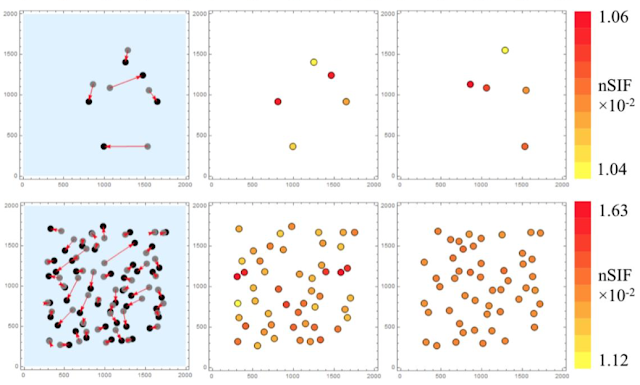

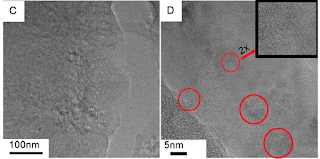

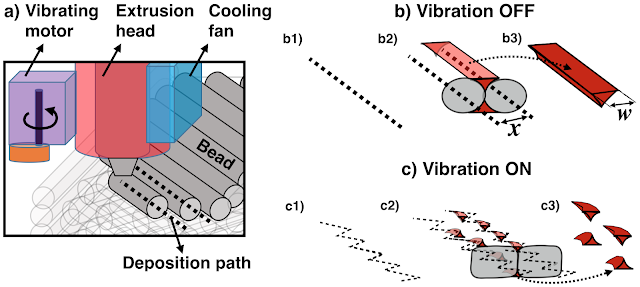

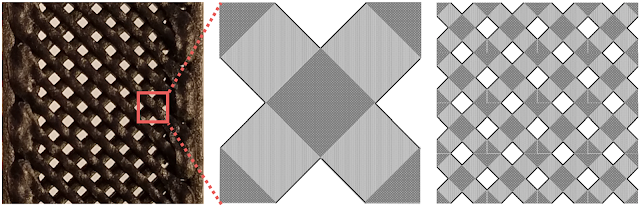

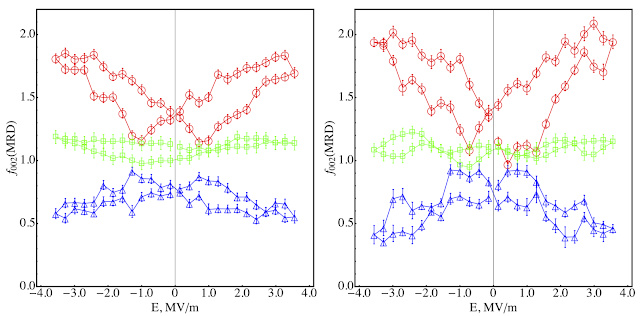

I will be collaborating with Palo Alto Research Center (formerly Xerox PARC) on a Department of Energy (DOE) grant shooting for enhanced properties in lead-free piezoelectric materials. We will apply high-throughput (HT) processing and characterization techniques on piezoceramics. This unique HT data will enable materials informatics approaches to guide our experiments towards higher performance systems. Figure. […]

Read More

New Department of Energy (DOE) grant on Scalable Ceramic ALignment for Electro-active Structures (SCALES)

- September 13, 2020

- Comments off