New paper on VA-FDM: Vibration-assisted FDM

- Post by: siteadmin

- February 17, 2018

- Comments off

Mechanical reliability of short carbon fiber reinforced ABS produced via vibration assisted fused deposition modeling

Özgür Keleş, Eric H. Anderson, and Jimmy Huynh

Biomedical, Chemical and Materials Engineering Department, San Jose State University, San Jose, California, USA

Rapid Prototyping Journal

Structured Abstract:

Purpose — Mechanical reliability (variations in mechanical properties) of fused deposition modeled (FDMed) short-fiber-reinforced composites are unknown, which limits wider and safer use of these composites. Accordingly, this paper investigated the mechanical reliability of FDMed model material short-carbon-fiber-reinforced acrylonitrile butadiene styrene (SCFR-ABS). A new vibration- assisted FDM (VA-FDM) process was used to reduce porosity.

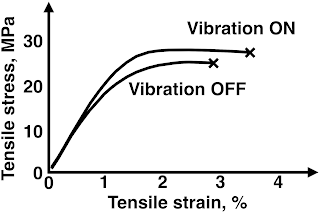

Design/methodology/approach — Tensile tests were performed on FDMed SCFR-ABS produced with and without vibrations. Weibull analysis was performed to quantify the variation in fracture strength, tensile strength, strain at break, and strain at tensile strength.

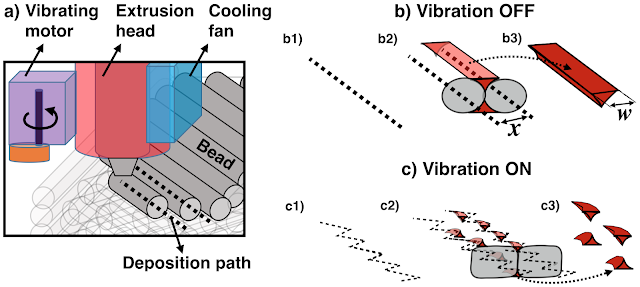

Findings — Introduction of vibrations to the extrusion head during FDM decreased the inter-bead porosity in SCFR-ABS; thus improved elastic modulus, toughness, fracture strength, tensile strength, and strain at break. Weibull modulus of fracture strength increased from 25 to 57 with vibrations.

Practical implications — The reported Weibull analysis offers a practical design guideline to predict failure rates at specific service stresses.

Originality/value — A detailed Weibull analysis of the variations in the mechanical properties of FDMed SCFR-ABS was performed for the first time. A new vibration assisted FDM process was reported to reduce inter-bead porosity in FDMed composites.

Keywords:

Porous materials, 3D printing, fused filament fabrication, mass customization, mass production

Click here for the PDF.

Figure: a) Schematic showing the FDM process and vibration motor at the extrusion head; b and c) schematic showing the changes in deposition path, inter-bead porosity and deposition path, and isolated inter-bead pores when the vibrations are on and off.

Figure: Stress-strain diagram for specimens produced with vibrations on-VA-FDM and normal FDM without any induced vibrations.

Posted 17th February 2018 by Ozgur Keles