New paper: Effect of build orientation on the mechanical reliability of 3D printed ABS

- Post by: siteadmin

- August 6, 2016

- Comments off

We investigated the effects of build orientation on the mechanical reliability of 3D printed ABS using a Stratasys uPrint SE. Thanks to my undergraduate researcher Caleb W. Blevins (second author), we were able to generate 262 specimens and test their mechanical behavior. The most important finding is that the reliability of FDM produced ABS can be as low as advanced ceramics. This paper will appear in the Rapid Prototyping Journal, vol:23, iss:2. Please click for the accepted manuscript.

Effect of build orientation on the mechanical reliability of 3D printed ABS

Özgür Keleş (a), Caleb W. Blevins (b) , Keith J. Bowman (c)

a. Biomedical, Chemical and Materials Engineering Department, San Jose State University, San Jose, California, USA

b. Mechanical Engineering Department, San Jose State University, San Jose, California, USA

c. College of Science and Engineering, San Francisco State University, San Francisco, California, USA

Abstract

Purpose – Increasing use of 3D printing techniques to manufacture consumer products and open source designs raises the question of “What is the mechanical reliability of 3D printed parts?” Therefore, the purpose of this paper is to investigate the effects of build orientation on the mechanical reliability of acrylonitrile butadiene styrene (ABS) produced using 3D printing.

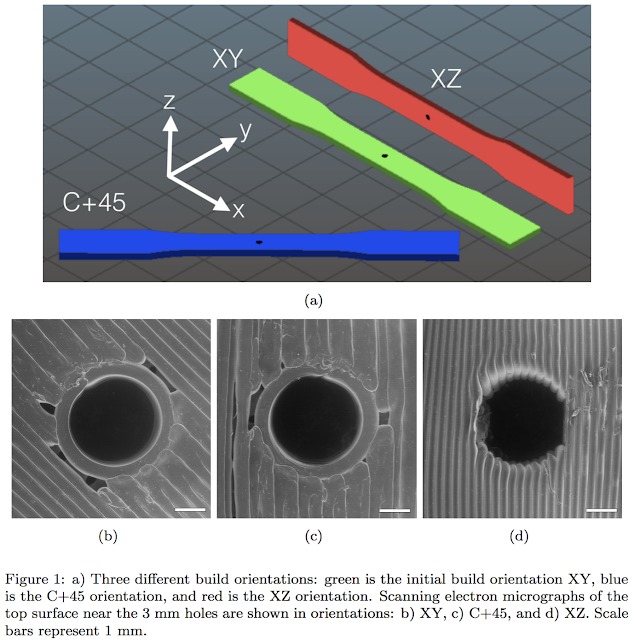

Design/methodology/approach – We performed tensile tests on ABS specimens with and without a hole in the center, which were produced by fused deposition modeling (FDM). Seven sets of ~30 specimens were printed in XY, XZ, and C+45 orientations to obtain reliable fracture statistics. Weibull analysis was performed to quantify the variation in the tensile strength.

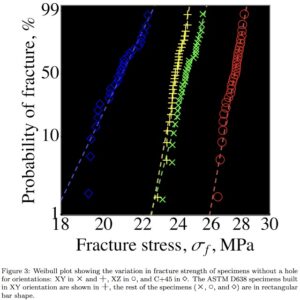

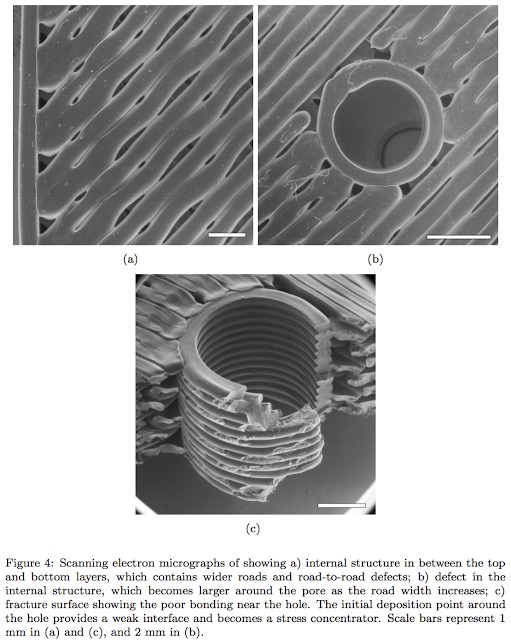

Findings – Weibull analysis showed that the reliability of FDM produced ABS can be as low as advanced ceramics. Weibull moduli of specimens without a hole were between 26 and 69 and specimens with a hole had Weibull moduli between 30 and 41. P-type deviations from the Weibull statistics were observed. The XZ orientation resulted in the highest average fracture strength for specimens with and without a hole and C+45 orientation resulted in the lowest strength.

Practical implications –As the Weibull distribution relates the applied stress to probability of failure, Weibull analysis provides a practical design criterion to achieve specific reliability levels for additively manufactured parts.

Originality/value –This study, for the first time, provides Weibull statistics for FDM produced ABS parts, which can be used to predict mechanical reliability.

Keywords: Mass production, mass customization, additive manufacturing, stress concentration, anisotropy

Posted 6th August 2016 by Ozgur Keles