Dei Rossi, Joseph, Ozgur Keles, and Vimal Viswanathan. “Fused Deposition Modeling with Induced Vibrations: A Study on the Mechanical Characteristics of Printed Parts.” Applied Sciences 12.18 (2022): 9327.

Abstract: The recent development of RepRap style 3D printers has made additive manufacturing technology available to the public at a low cost. While these 3D printers are being used for a variety of purposes, one of the main applications is prototyping in design projects. The quality of the 3D-printed parts has been a concern in such cases. Many variables within these printers’ operation can be varied to obtain optimum print quality. This study explores a setup that uses externally induced mechanical vibrations to the nozzle tip as a potential method to improve the quality of 3D-printed parts. Induced vibration is expected to decrease the porosity of printed parts and enhance the cohesion between print beads, ultimately improving their mechanical properties. The objective is to understand the prints’ positional accuracy, porosity, and mechanical properties with the added vibration and then to determine the optimum vibration level to achieve the best quality prints. While previous studies have explored the role of induced vibration on the mechanical properties of printed parts, the novelty of this work lies in the determination of the positional accuracy of those parts and the determination of optimum vibration levels to achieve desired properties. For positional accuracy, the extruder filament is replaced with a pointed-tip pen that can mark the exact __cpLocation where the printer delivers the material. A comparison between the __cpLocations marked by the pen with and without vibrations shows that the errors induced by the added vibration are not significantly different from those caused by the uncertainties of the printer itself. Based on the tensile tests of the printed specimens, it is concluded that the parts printed with induced vibrations have improved mechanical properties. The printed parts’ porosity is reduced significantly due to the induced vibrations. Further, this study also explores the optimum motor speeds to achieve a uniform distribution of material. It determines medium motor speeds that provide a maximum vibration amplitude, which is more desirable for a consistent infill.

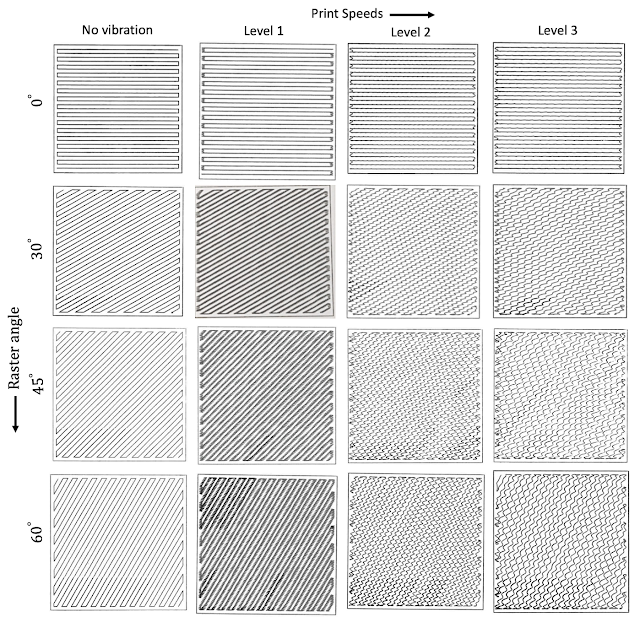

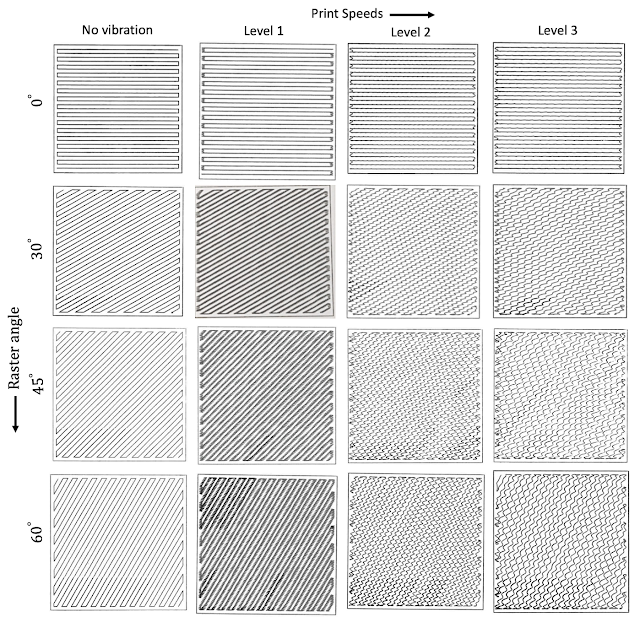

Variation in the infifilloftheprriintteedpaarrtstswitihthininccrereaasisninggpprirnitnstpsepedesdfsofrodridffieffrernetnstasntadnadrd- ard raster angle

Posted 2nd September 2022 by Ozgur Keles