New NSF MRI grant to acquire a metal additive manufacturing system

- Post by: siteadmin

- August 31, 2019

- Comments off

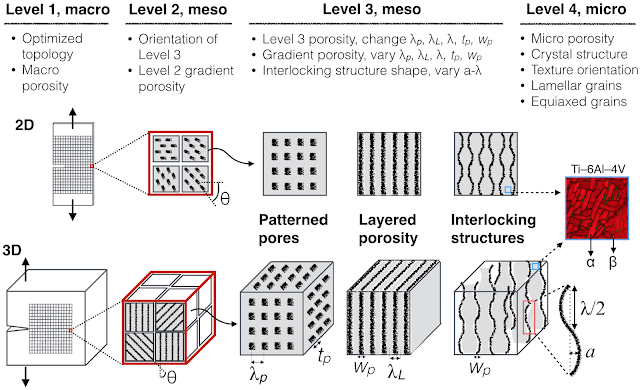

We will be installing a new EOS M 100 metal additive manufacturing system. Our research is targeting unexplored hierarchical structural spaces that can be achieved using the unique capabilities of the selective laser melting system. I would like to thank my co-PIs, collaborators, NSF officials, and reviewers, including Birsen Sirkeci, Feruza Amirkulova, Raymond K. Yee, David Yan, Cem Tasan, James Palko, Andrew Norris, Vijaya Chalivendra, Farshid Marbouti, Gilles Eggenspieler, Quyen Chu, and Jo Culbertson.

Figure: Our approach towards hierarchical SLMed metals.

MRI: Acquisition of a metal additive manufacturing system for multi-disciplinary research and education at a minority-serving institution

ABSTRACT:

This Major Research Instrumentation (MRI) award provides funding to acquire a metal additive manufacturing (AM) system for research and education. The instrumentation will enable researchers to develop new knowledge on the production of metals with high fracture and fatigue resistance, which are needed for the biomedical, defense, aerospace, and automotive industries. The instrumentation will also catalyze research advances in novel on-demand design of metamaterials for acoustic cloaking, biomedical imaging, and health monitoring. The metal AM system will enrich graduate and undergraduate education, support outreach activities at K-12 schools, and aid teacher workshops. A new virtual reality metal AM teaching module will be developed and made available for engineering students, high-school students, and the public. Research findings will also provide the basis for a new machine learning and computational mechanics class.

The requested metal AM system will provide structural information on defects and pores that can be processed at the micro- and meso-scale, providing insights into the processing limits of the SLM system. A new SPH model will be developed to understand the powder-level physics during the SLM process; thus, advancing fundamental understanding of the structure development during the SLM of hierarchical metals. Neutron diffraction will be used to reveal the processing/structure effects on the residual stresses in hierarchical SLMed metals. Mechanical behavior of the hierarchical metals will be observed via tensile and fracture toughness tests. Using this new processing-structure-property information, FEM simulations will be performed to discover the origins of hierarchical toughening mechanisms in SLMed metals.

Posted 31st August 2019 by Ozgur Keles

Categories: Uncategorized