Bacteria rule the world, new paper in ACS Omega

- Post by: Ozgur Keles

- February 6, 2025

- Comments off

Comparison of the Macro Chain Transfer Agent and the Macro Azo Initiator Based on the Poly(3-hydroxy Butyrate) in the Polymerization Kinetics of Methyl Methacrylate

Baki Hazer and Özgür Keleş

You can access here link.

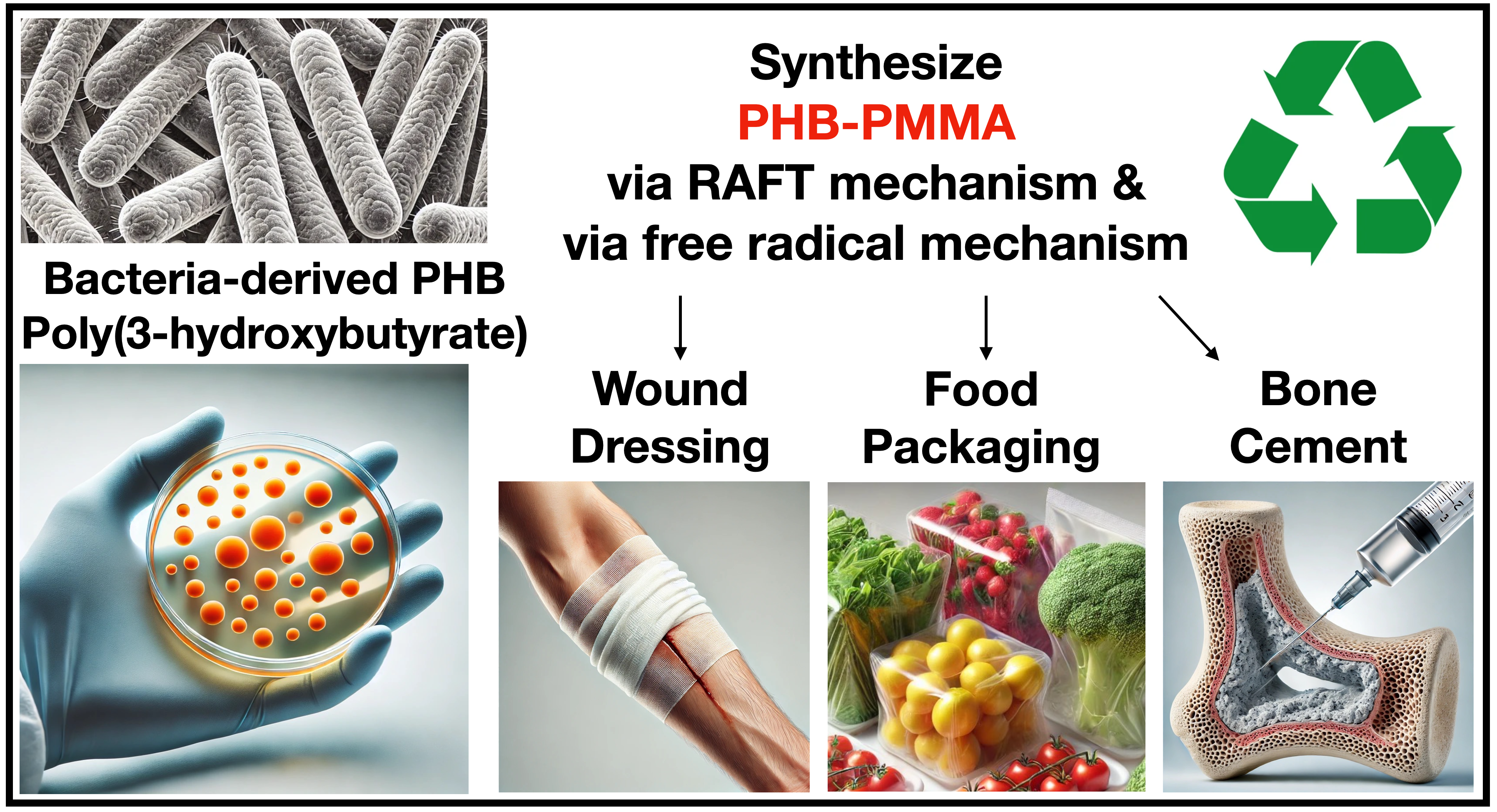

Abstract: Poly(3-hydroxybutyrate) (PHB) derivatives are attractive for sustainable polymer production, yet their role in controlling radical polymerization kinetics remains underexplored. In this study, we compare the polymerization kinetics of methyl methacrylate (MMA) using two PHB-based macroinitiators: a macro chain transfer agent (PHB-macro reversible addition-fragmentation chain transfer (RAFT)) and a macroazo initiator (PHBai). RAFT polymerizations (PHB-R-PMMA) were conducted at 70 °C with PHB-macro RAFT in the presence of 2,2′-azobis(isobutyronitrile), while conventional free radical polymerizations (PHBaiPMMA) were carried out using PHBai under identical conditions. The RAFT system exhibited a slightly lower overall rate constant (k = 1.11 × 10–4 L/mol·s) compared to the azo-initiated system (k = 1.28 × 10–4 L/mol·s). Both systems showed a gradual decrease in the PHB content over time, indicating effective copolymer formation with increasing MMA incorporation. Activation energies for PHB-macro RAFT and PHBai were calculated as 0.88 and 1.05 kJ/mol, respectively, demonstrating RAFT’s superior control over molecular architecture. The resulting PHB-PMMA block copolymers offer promising applications in orthopedic surgery (e.g., bone cements), packaging, medical implants, drug delivery, and dental materials. This study provides the first direct comparison of PHB-based macro RAFT and azo systems for MMA polymerization, highlighting RAFT’s advantage in achieving controlled polymer architectures and expanding biomedical and industrial utility.